Best quality Thermo-Electric Alloys - Fe-Cr-Al alloys – Shougang

Best quality Thermo-Electric Alloys - Fe-Cr-Al alloys – Shougang Detail:

Fe-Cr-Al alloys is one of the most widely used electrothermal alloys at home and abroad. It is characterized by high resistivity, small resistance temperature coefficient, good oxidation resistance, high temperature and so on . These alloys are widely used in making industrial heating equipments and domestic heating appliances. Fe-Cr-Al alloys are one of the main products of our company. All resistance heating alloys manufactured by our company are distinguished by uniform composition, high resistivity, accurate dimension, long operating life and good processability. Consumers can select the suitable grade according to different requirements.

SG-GITANE’S resistance heating wire 0Cr25Al5 obtained the title of excellent grade product from the China Ministry of Metallurgical Industry. In 1983, the company’s resistance heating wire HRE awarded the second rate prize for the progress in science and technology from Beijing Municipality.

Size range

|

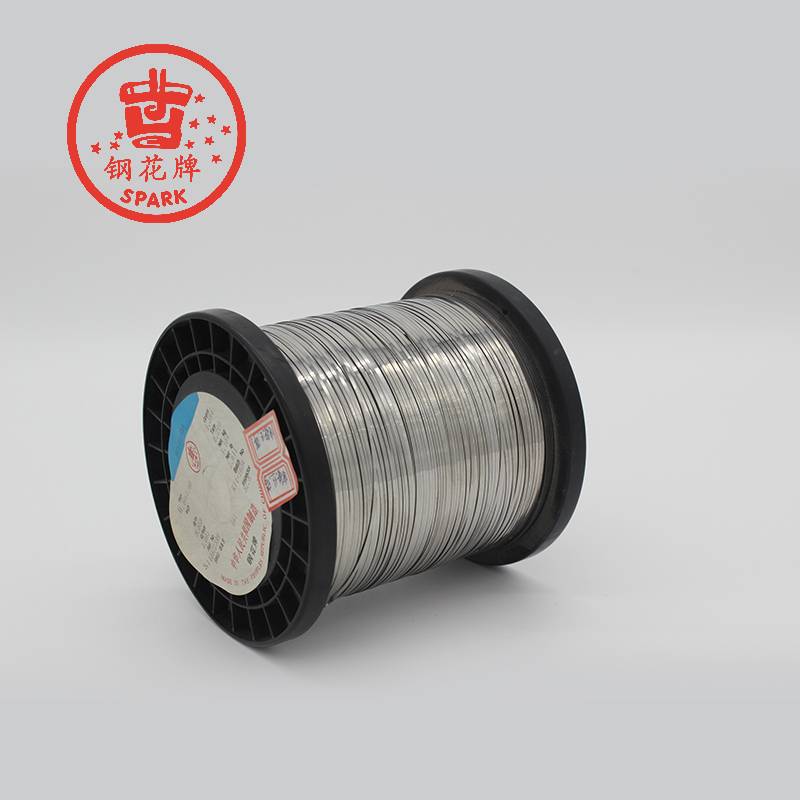

Wire |

Ø0.03—10.00mm |

|

Wire rod |

Ø5.50—12.00mm |

|

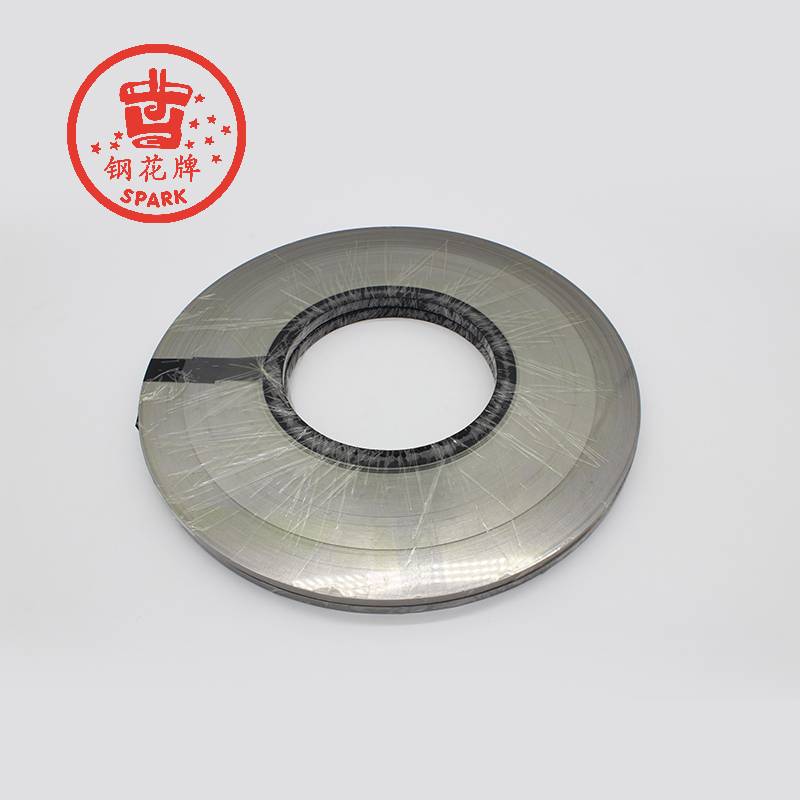

Ribbon |

Thickness 0.05—0.35mm |

|

|

Width 0.5—4.5mm |

|

Strip |

Thickness 0.5—2.5mm |

|

|

Width 5.0—48.0mm |

|

Hot rolled strip |

Thickness 4.0—6.0mm |

|

|

Width 15.0—38.0mm |

|

Steel bar |

Ø10.0—20.0mm |

Chemical Composition of Stainless Steels

|

Properties |

0Cr21Al6Nb |

0Cr25Al5 |

0Cr23Al5 |

0Cr19Al5 |

0Cr19Al3 |

1Cr13Al4 |

|

Nominal composition Cr Al Fe Ni |

24.0 6.0 Rest —— |

25.0 5.3 Rest —— |

22.0 5.0 Rest —— |

19.0 5.0 Rest —— |

19.0 3.7 Rest —— |

13.5 5.0 Rest —— |

|

Max.continuous operating temperature℃ |

1400 |

1300 |

1250 |

1200 |

1100 |

950 |

|

Temperature factor of the resistivityCt 800℃ 1000℃ 1200℃ |

1.03 1.04 1.04 |

1.05 1.06 1.06 |

1.06 1.07 1.08 |

1.05 1.06 1.06 |

1.17 1.19 —— |

1.13 1.14 —— |

|

Density(g/cm3) |

7.10 |

7.15 |

7.25 |

7.20 |

7.35 |

7.40 |

|

Melting point(approx.)(℃) |

1500 |

1500 |

1500 |

1500 |

1500 |

1450 |

|

Tensile strength(approx.)(N/mm2) |

750 |

750 |

750 |

750 |

750 |

750 |

|

Elongation at rupture(approx.)% |

16 |

16 |

16 |

16 |

16 |

16 |

|

Magnetic properties |

Magnetic |

Magnetic |

Magnetic |

Magnetic |

Magnetic |

Magnetic |

Product detail pictures:

Related Product Guide:

Every member from our high efficiency sales team values customers' needs and business communication for Best quality Thermo-Electric Alloys - Fe-Cr-Al alloys – Shougang , The product will supply to all over the world, such as: Melbourne, Paraguay, Ukraine, Item have passed by means of the national qualified certification and been well received in our main industry. Our expert engineering team will often be ready to serve you for consultation and feedback. We have been able to also deliver you with cost-free samples to meet your specs. Ideal efforts will probably be produced to deliver you the most beneficial service and solutions. Should really you be interested in our company and solutions, please make contact with us by sending us emails or call us straight away. To be able to know our solutions and enterprise. ar more, you'll be able to come to our factory to see it. We will constantly welcome guests from all over the world to our firm. o build business enterprise. elations with us. You should feel absolutely free to speak to us for organization. nd we believe we are going to share the best trading practical experience with all our merchants.

We have been engaged in this industry for many years, we appreciate the work attitude and production capacity of the company, this is a reputable and professional manufacturer.