Good Quality Electric Heating Wire - Fe-Cr-Al alloys – Shougang

Good Quality Electric Heating Wire - Fe-Cr-Al alloys – Shougang Detail:

Fe-Cr-Al alloys is one of the most widely used electrothermal alloys at home and abroad. It is characterized by high resistivity, small resistance temperature coefficient, good oxidation resistance, high temperature and so on . These alloys are widely used in making industrial heating equipments and domestic heating appliances. Fe-Cr-Al alloys are one of the main products of our company. All resistance heating alloys manufactured by our company are distinguished by uniform composition, high resistivity, accurate dimension, long operating life and good processability. Consumers can select the suitable grade according to different requirements.

SG-GITANE’S resistance heating wire 0Cr25Al5 obtained the title of excellent grade product from the China Ministry of Metallurgical Industry. In 1983, the company’s resistance heating wire HRE awarded the second rate prize for the progress in science and technology from Beijing Municipality.

Size range

|

Wire |

Ø0.03—10.00mm |

|

Wire rod |

Ø5.50—12.00mm |

|

Ribbon |

Thickness 0.05—0.35mm |

|

|

Width 0.5—4.5mm |

|

Strip |

Thickness 0.5—2.5mm |

|

|

Width 5.0—48.0mm |

|

Hot rolled strip |

Thickness 4.0—6.0mm |

|

|

Width 15.0—38.0mm |

|

Steel bar |

Ø10.0—20.0mm |

Chemical Composition of Stainless Steels

|

Properties |

0Cr21Al6Nb |

0Cr25Al5 |

0Cr23Al5 |

0Cr19Al5 |

0Cr19Al3 |

1Cr13Al4 |

|

Nominal composition Cr Al Fe Ni |

24.0 6.0 Rest —— |

25.0 5.3 Rest —— |

22.0 5.0 Rest —— |

19.0 5.0 Rest —— |

19.0 3.7 Rest —— |

13.5 5.0 Rest —— |

|

Max.continuous operating temperature℃ |

1400 |

1300 |

1250 |

1200 |

1100 |

950 |

|

Temperature factor of the resistivityCt 800℃ 1000℃ 1200℃ |

1.03 1.04 1.04 |

1.05 1.06 1.06 |

1.06 1.07 1.08 |

1.05 1.06 1.06 |

1.17 1.19 —— |

1.13 1.14 —— |

|

Density(g/cm3) |

7.10 |

7.15 |

7.25 |

7.20 |

7.35 |

7.40 |

|

Melting point(approx.)(℃) |

1500 |

1500 |

1500 |

1500 |

1500 |

1450 |

|

Tensile strength(approx.)(N/mm2) |

750 |

750 |

750 |

750 |

750 |

750 |

|

Elongation at rupture(approx.)% |

16 |

16 |

16 |

16 |

16 |

16 |

|

Magnetic properties |

Magnetic |

Magnetic |

Magnetic |

Magnetic |

Magnetic |

Magnetic |

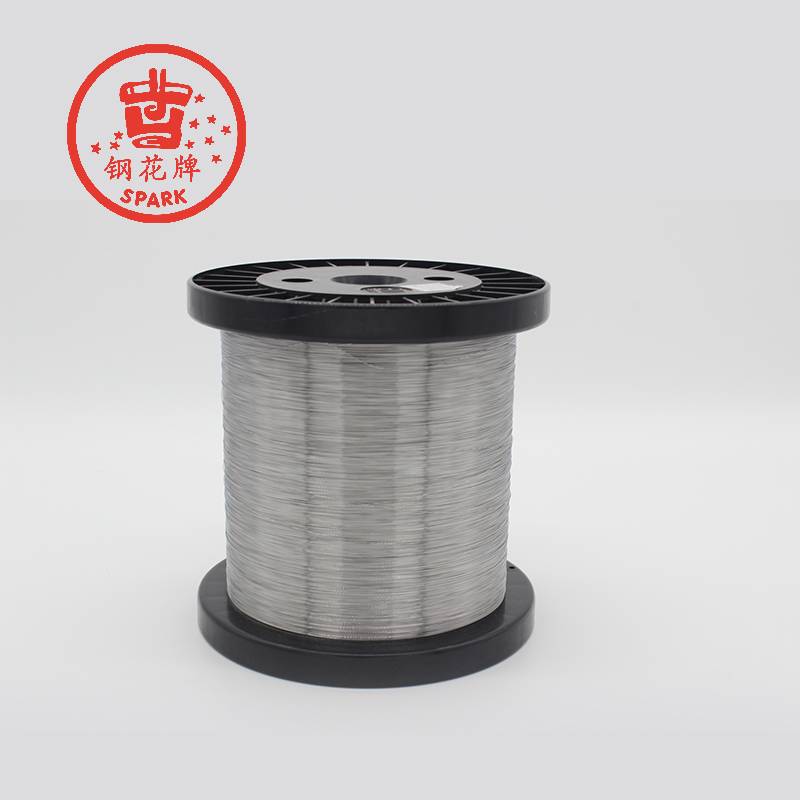

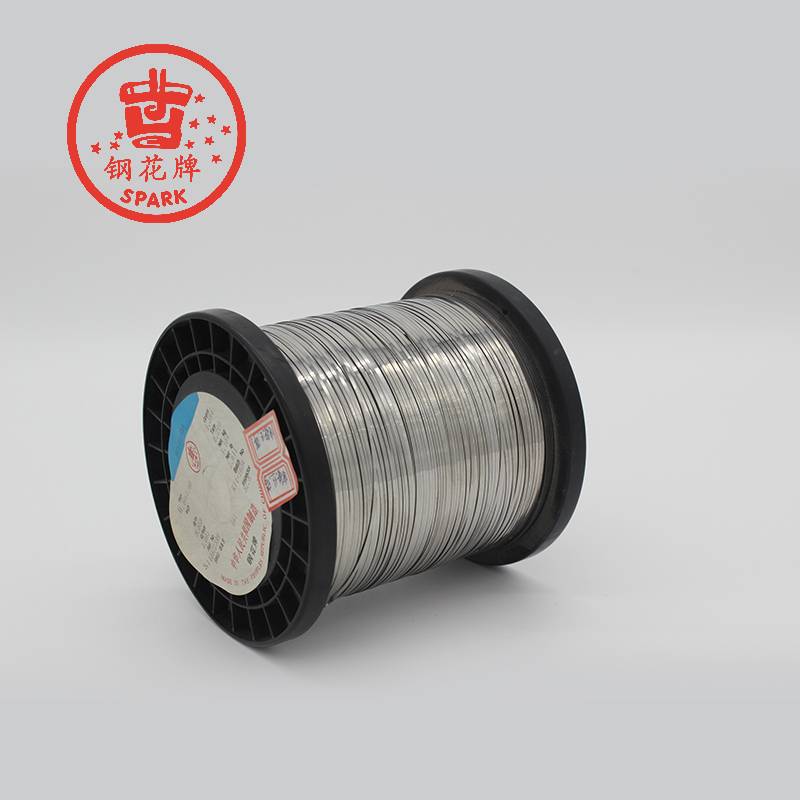

Product detail pictures:

Related Product Guide:

We're also concentrating on improving the things administration and QC program to ensure we could maintain terrific gain from the fiercely-competitive company for Good Quality Electric Heating Wire - Fe-Cr-Al alloys – Shougang , The product will supply to all over the world, such as: USA, Zurich, Milan, Looking forward, we will keep pace with the times, continuing to create new products. With our strong research team, advanced production facilities, scientific management and top services, we will supply high quality products to our customers worldwide. We sincerely invite you to be our business partners for mutual benefits.

After the signing of the contract, we received satisfactory goods in a short term, this is a commendable manufacturer.