Good quality FE CR AL High Heat Electrical Wire - Ni-Cr alloys – Shougang

Good quality FE CR AL High Heat Electrical Wire - Ni-Cr alloys – Shougang Detail:

Ni-Cr electrothermal alloy has high temperature strength. It has good toughness and does not easily deform. Its grain structure is not easily changed. The plasticity is better than Fe-Cr-Al alloys. No brittleness after high temperature cooling, long service life, its easy to process and welding, but the service temperature is lower than Fe-Cr-Al alloy. Ni-Cr electrothermal alloys are one of the main products of our company. All resistance heating alloys manufactured by our company are distinguished by uniform composition, high resistivity, stable quality, accurate dimension, long operating life and good processability. Consumers can select the suitable grade according to different requirements.

Steel grades and Chemical composition(GB/T1234-1995)

|

Steel grades |

Chemical composition(%) |

||||

|

|

C |

Si |

Cr |

Ni |

Fe |

|

Cr15Ni60 |

≤0.08 |

0.75-1.6 |

15-18 |

55-61 |

- |

|

Cr20Ni30 |

≤0.08 |

1-2 |

18-21 |

30-34 |

- |

|

Cr20Ni35(N40) |

≤0.08 |

1-3 |

18-21 |

34-37 |

- |

|

Cr20Ni80 |

≤0.08 |

0.75-1.6 |

20-23 |

remain |

≤1 |

|

Cr30Ni70 |

≤0.08 |

0.75-1.6 |

28-31 |

remain |

≤1 |

(According to the needs of customers, we can provide alloys in accordance with the enterprise standards, such as American standard, Japanese standard, German standard and other standards)

Properties and Applications

|

Steel grades |

Max.continuous operating temperature℃ |

Tensile strength N/mm2 |

Elongation at rupture(approx.)% |

Electrical resistivity μ·Ω·m |

|

Cr15Ni60 |

1150℃ |

700-900 |

>25 |

1.07-1.20 |

|

Cr20Ni30 |

1050℃ |

700-900 |

>25 |

0.99-1.11 |

|

Cr20Ni35(N40) |

1100℃ |

700-900 |

>25 |

0.99-1.11 |

|

Cr20Ni80 |

1200℃ |

700-900 |

>25 |

1.04-1.19 |

|

Cr30Ni70 |

1250℃ |

700-900 |

>25 |

1.13-1.25 |

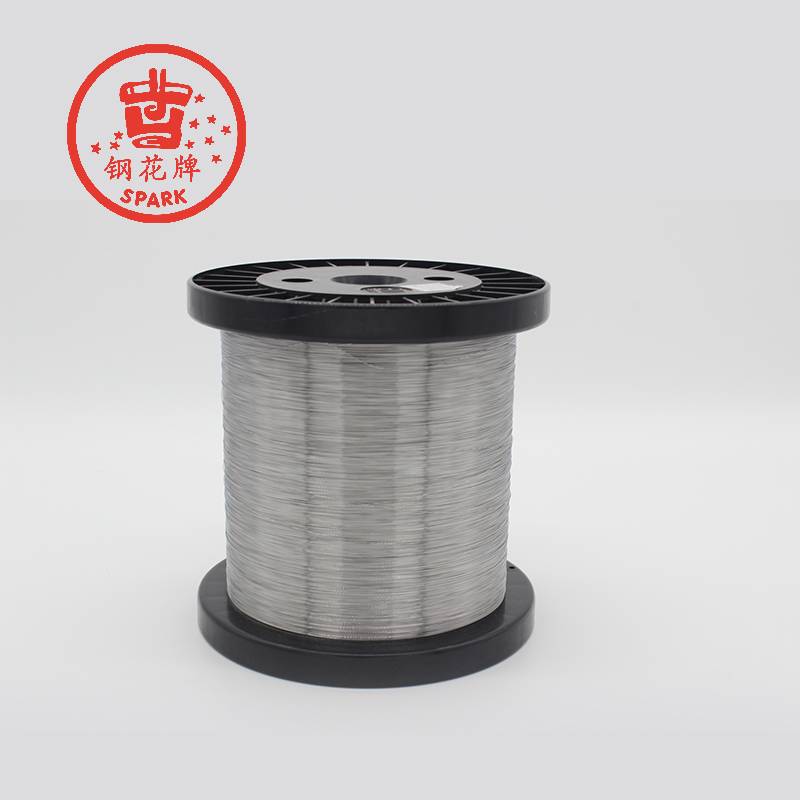

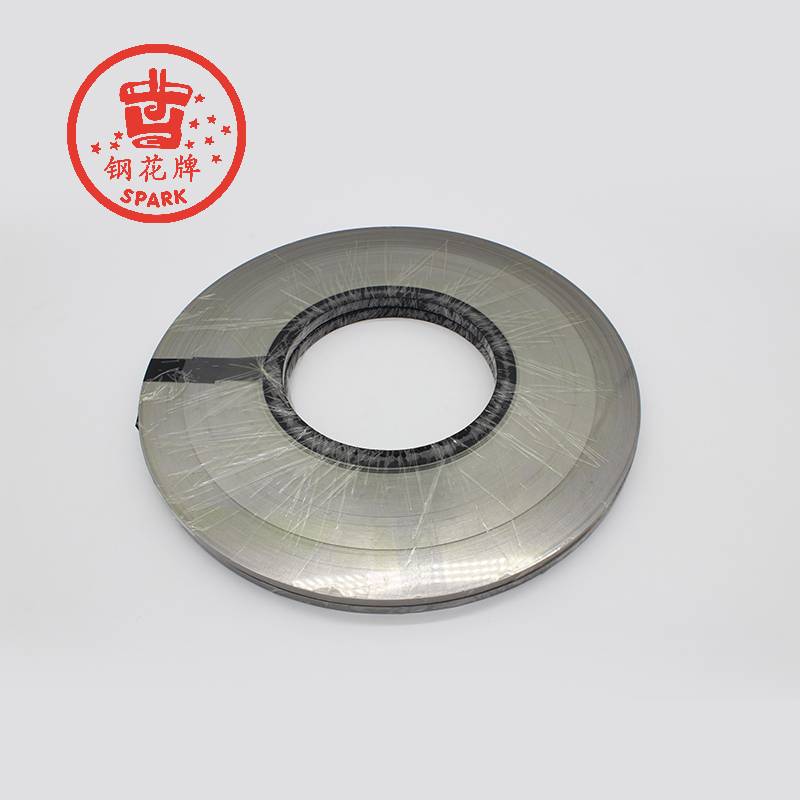

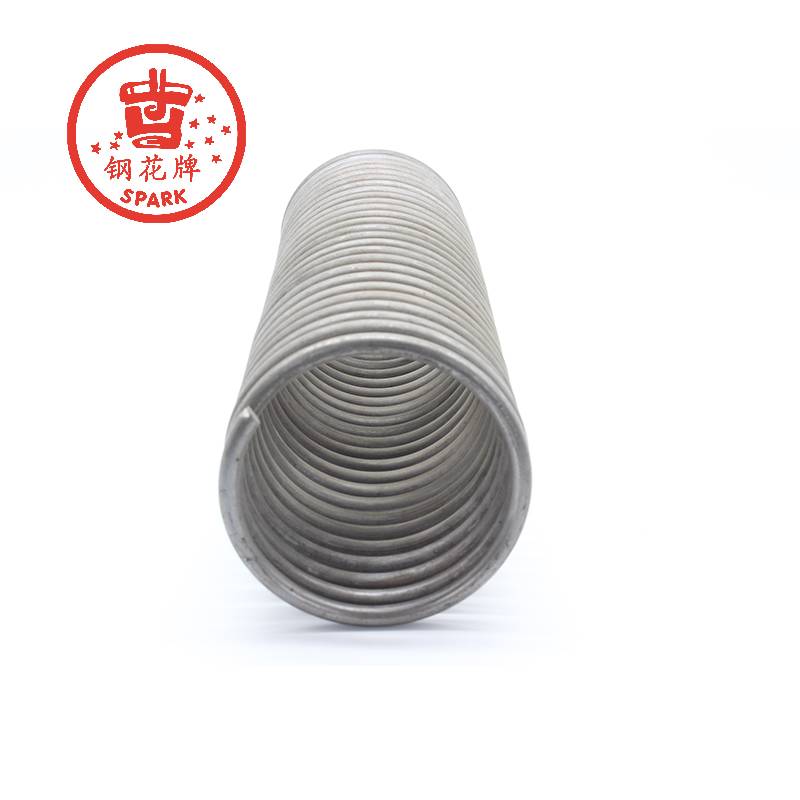

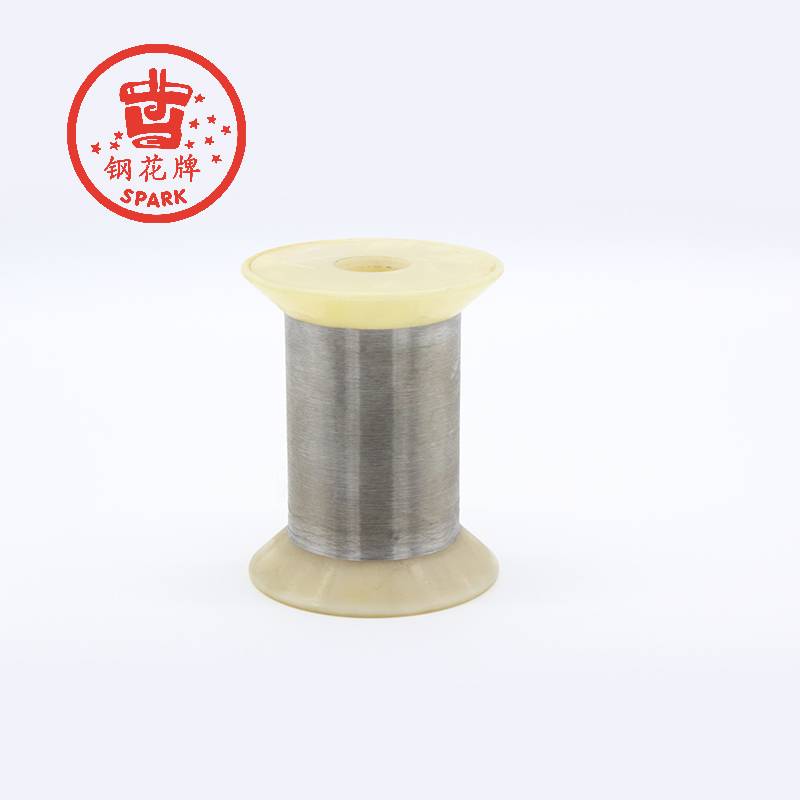

Size range

|

Wire diameter |

Ø0.05—8.0mm |

|

Ribbon |

Thickness 0.08—0.4mm |

|

|

Width 0.5—4.5mm |

|

Strip |

Thickness 0.5—2.5mm |

|

|

Width 5.0—48.0mm |

Product detail pictures:

Related Product Guide:

Our merchandise are commonly recognized and reliable by customers and can meet constantly developing economic and social desires for Good quality FE CR AL High Heat Electrical Wire - Ni-Cr alloys – Shougang , The product will supply to all over the world, such as: Serbia, Bangalore, Anguilla, We warmly welcome you to come to visit us personally. We hope to establish a long-term friendship based on equality and mutual benefit. If you want to get in touch with us, please do not hesitate to call. We will be your best choice.

Although we are a small company, we are also respected. Reliable quality, sincere service and good credit, we are honored to be able to work with you!