Good quality SHOUGANG High Temperature Alloys tube - SGHYZ high temperature electrothermal alloy – Shougang

Good quality SHOUGANG High Temperature Alloys tube - SGHYZ high temperature electrothermal alloy – Shougang Detail:

BEIJING SHOUGANG GITANE NEW MATERIALS CO.LTD has long been committed to the research and development of electric heating alloy products with good oxidation resistance and high temperature resistance. SGHYZ product is a new product developed after HRE which has been widely used in high temperature electrothermal alloy materials in recent years. Compared with HRE, SGHYZ product has higher purity and better oxidation resistance. With the special rare earth element collocation and unique metallurgical manufacturing process, the material has been recognized by domestic and foreign customers in the field of high-temperature heat-resistant fiber. It has been successfully applied in ceramic sintering, diffusion furnace, high power density and high temperature industrial kiln.

1. grades and chemical composition%

| C | Si | Cr | Al | Fe |

| ≤0.04 | ≤0.4 | 20-23 | 5.8 | - |

2. Specifications

(1) Diameter of round wire:φ0.15-9.0mm

(2) Flat wire thickness:0.1-0.4mm Width:0.5-4.5mm

(3)Strip thickness: 0.5-2.5 Width:5-48mm

3. Delivery status

(1) The diameter of the wire is larger than 5.0 mm,Blue disc delivery

(2) Wire diameter range: 1.0-5.0 mm, golden plate delivery

(3) Wire diameter range is less than or equal to φ 1.0 mm, bright axial delivery

(4) Flat belt: delivered in polished condition.

4. Performance and Application

(1). Basic application

| Maximum usetemperature℃ | Annealed tensile strength N/mm2 | Elongation % | 20℃resistancerateμ.Ω.m |

|

1425 |

650-800 |

>14 |

1.45 |

Application: High temperature ceramic firing furnace / high temperature heat treatment furnace / high temperature diffusion in electronic industry

(2).Characteristics

| densityg/cm3 | 1000℃high temperaturestrength MPa | 1350 ℃ fast life (hoursAccording to GB / t13300-91 standard | Completely oxidized stateRadiation coefficient of |

| 7.1 | 20 | >80 | 0.7 |

(3)、Average linear expansion coefficient

| temperature℃ | Average linear expansion coefficien×10-6/k |

| 20-250 |

11 |

| 20-500 |

12 |

| 20-750 |

14 |

| 20-1000 |

15 |

(4).Resistance temperature correction factor

| temperature℃ | 700 | 900 | 1100 | 1200 | 1300 |

| Ct | 1.02 | 1.03 | 1.04 | 1.04 | 1.04 |

5. Relative life

| Wire specifications(mm) | Resistance(Ω/m) | Weight(g/m) |

| 1 | 1.85 | 5.58 |

| 1.1 | 1.53 | 6.75 |

| 1.2 | 1.28 | 8.03 |

| 1.3 | 1.09 | 9.42 |

| 1.4 | 0.942 | 10.9 |

| 1.5 | 0.821 | 12.5 |

| 1.6 | 0.721 | 14.3 |

| 1.7 | 0.639 | 16.1 |

| 1.8 | 0.57 | 18.1 |

| 1.9 | 0.511 | 20.1 |

| 2 | 0.462 | 22.3 |

| 2.1 | 0.419 | 24.6 |

| 2.2 | 0.381 | 27 |

| 2.3 | 0.349 | 29.5 |

| 2.4 | 0.321 | 32.1 |

| 2.5 | 0.295 | 34.9 |

| 2.6 | 0.273 | 37.7 |

| 2.7 | 0.253 | 40.7 |

| 2.8 | 0.235 | 43.7 |

| 2.9 | 0.22 | 46.9 |

| 3 | 0.205 | 50.2 |

| 3.1 | 0.192 | 53.6 |

| 3.2 | 0.18 | 57.1 |

| 3.3 | 0.17 | 60.7 |

| 3.4 | 0.16 | 64.5 |

| 3.5 | 0.151 | 68.3 |

| 3.6 | 0.142 | 72.3 |

| 3.7 | 0.135 | 76.3 |

| 3.8 | 0.128 | 80.5 |

| 3.9 | 0.121 | 84.8 |

| 4 | 0.115 | 89.2 |

| 4.1 | 0.11 | 93.7 |

| 4.2 | 0.105 | 98.4 |

| 4.3 | 0.1 | 103.1 |

| 4.4 | 0.095 | 108 |

| 4.5 | 0.0912 | 113 |

| 4.6 | 0.0873 | 118 |

| 4.7 | 0.0836 | 123 |

| 4.8 | 0.0801 | 128 |

| 4.9 | 0.0769 | 134 |

| Wire specifications(mm) | Resistance(Ω/m) | Weight(g/m) |

| 5 | 0.0739 | 139 |

| 5.1 | 0.071 | 145 |

| 5.2 | 0.0683 | 151 |

| 5.3 | 0.0657 | 157 |

| 5.4 | 0.0633 | 163 |

| 5.5 | 0.061 | 169 |

| 5.6 | 0.0589 | 175 |

| 5.7 | 0.0568 | 181 |

| 5.8 | 0.0549 | 188 |

| 5.9 | 0.053 | 194 |

| 6 | 0.0513 | 201 |

| 6.1 | 0.0496 | 207 |

| 6.2 | 0.048 | 214 |

| 6.3 | 0.0465 | 221 |

| 6.4 | 0.0451 | 228 |

| 6.5 | 0.0437 | 236 |

| 6.6 | 0.0424 | 243 |

| 6.7 | 0.0411 | 250 |

| 6.8 | 0.0399 | 258 |

| 6.9 | 0.0388 | 265 |

| 7 | 0.0377 | 273 |

| 7.1 | 0.0366 | 281 |

| 7.2 | 0.0356 | 289 |

| 7.3 | 0.0346 | 297 |

| 7.4 | 0.0337 | 305 |

| 7.5 | 0.0328 | 314 |

| 7.6 | 0.032 | 322 |

| 7.7 | 0.0311 | 331 |

| 7.8 | 0.0303 | 339 |

| 7.9 | 0.0296 | 348 |

| 8 | 0.0288 | 357 |

| 8.1 | 0.0281 | 366 |

| 8.2 | 0.0275 | 375 |

| 8.3 | 0.0268 | 384 |

| 8.4 | 0.0262 | 393 |

| 8.5 | 0.0256 | 403 |

| 8.6 | 0.025 | 412 |

| 8.7 | 0.0244 | 422 |

| 8.8 | 0.0238 | 432 |

| 8.9 | 0.0233 | 442 |

SGHYZ meter resistance / weight reference table. (the above calculation data are only for reference, the resistance fluctuation range is ± 5%, and the weight varies with the size accuracy range.)

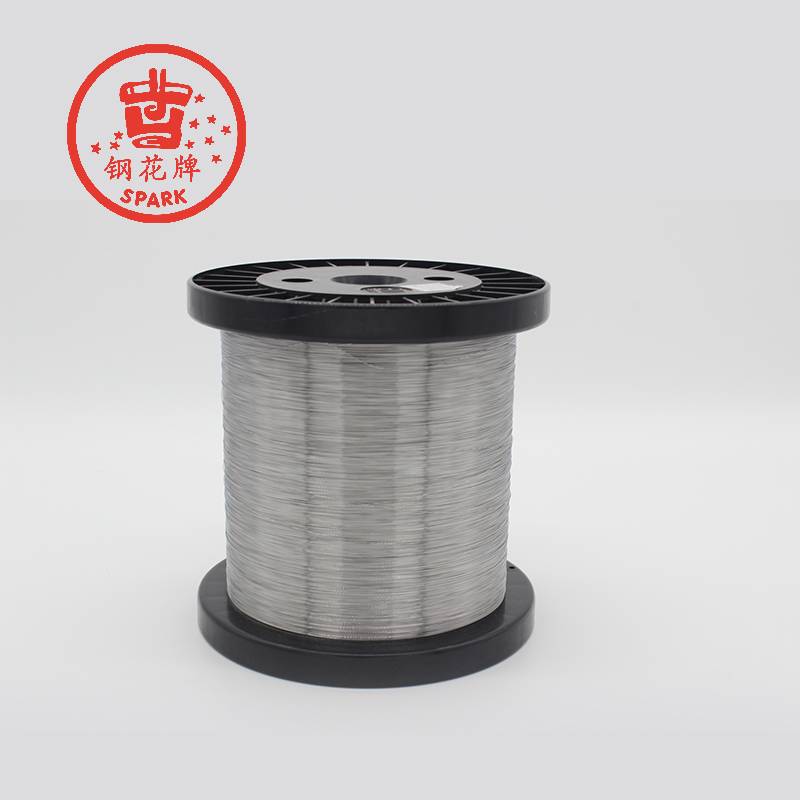

Product detail pictures:

Related Product Guide:

So as to provide you with ease and enlarge our business, we even have inspectors in QC Crew and guarantee you our best company and solution for Good quality SHOUGANG High Temperature Alloys tube - SGHYZ high temperature electrothermal alloy – Shougang , The product will supply to all over the world, such as: Japan, Armenia, Chile, For anyone who is keen on any of our items right after you view our product list, you should definitely feel absolutely free to get in touch with us for inquiries. You are able to send us emails and contact us for consultation and we shall respond to you as soon as we can. If it's easy, you may locate out our address in our web-site and come to our business for far more information of our merchandise by your self. We're always ready to construct extended and steady co-operation relations with any possible customers in the related fields.

High Quality, High Efficiency, Creative and Integrity, worth having long-term cooperation! Looking forward to the future cooperation!