Hot New Products Heat Resistant Insulation For Electrical Wire - Ni-Cr alloys – Shougang

Hot New Products Heat Resistant Insulation For Electrical Wire - Ni-Cr alloys – Shougang Detail:

Ni-Cr electrothermal alloy has high temperature strength. It has good toughness and does not easily deform. Its grain structure is not easily changed. The plasticity is better than Fe-Cr-Al alloys. No brittleness after high temperature cooling, long service life, its easy to process and welding, but the service temperature is lower than Fe-Cr-Al alloy. Ni-Cr electrothermal alloys are one of the main products of our company. All resistance heating alloys manufactured by our company are distinguished by uniform composition, high resistivity, stable quality, accurate dimension, long operating life and good processability. Consumers can select the suitable grade according to different requirements.

Steel grades and Chemical composition(GB/T1234-1995)

|

Steel grades |

Chemical composition(%) |

||||

|

|

C |

Si |

Cr |

Ni |

Fe |

|

Cr15Ni60 |

≤0.08 |

0.75-1.6 |

15-18 |

55-61 |

- |

|

Cr20Ni30 |

≤0.08 |

1-2 |

18-21 |

30-34 |

- |

|

Cr20Ni35(N40) |

≤0.08 |

1-3 |

18-21 |

34-37 |

- |

|

Cr20Ni80 |

≤0.08 |

0.75-1.6 |

20-23 |

remain |

≤1 |

|

Cr30Ni70 |

≤0.08 |

0.75-1.6 |

28-31 |

remain |

≤1 |

(According to the needs of customers, we can provide alloys in accordance with the enterprise standards, such as American standard, Japanese standard, German standard and other standards)

Properties and Applications

|

Steel grades |

Max.continuous operating temperature℃ |

Tensile strength N/mm2 |

Elongation at rupture(approx.)% |

Electrical resistivity μ·Ω·m |

|

Cr15Ni60 |

1150℃ |

700-900 |

>25 |

1.07-1.20 |

|

Cr20Ni30 |

1050℃ |

700-900 |

>25 |

0.99-1.11 |

|

Cr20Ni35(N40) |

1100℃ |

700-900 |

>25 |

0.99-1.11 |

|

Cr20Ni80 |

1200℃ |

700-900 |

>25 |

1.04-1.19 |

|

Cr30Ni70 |

1250℃ |

700-900 |

>25 |

1.13-1.25 |

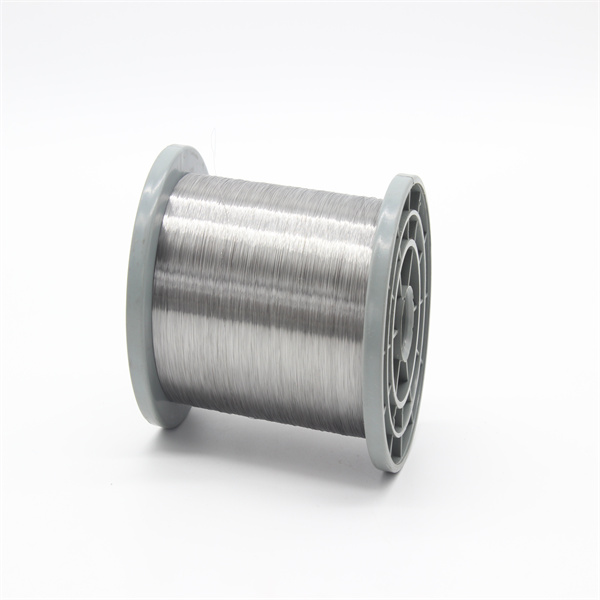

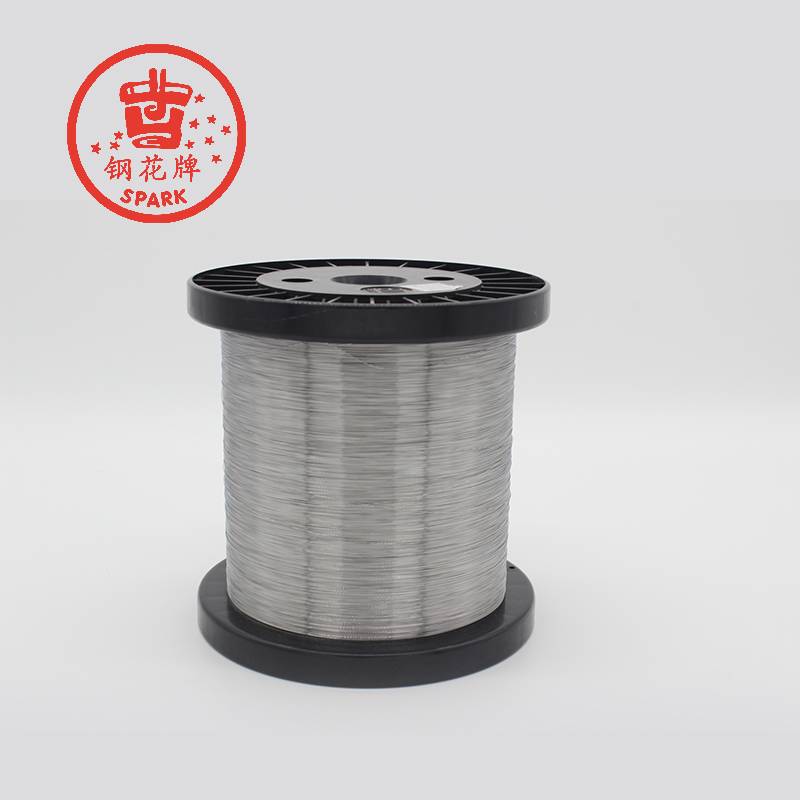

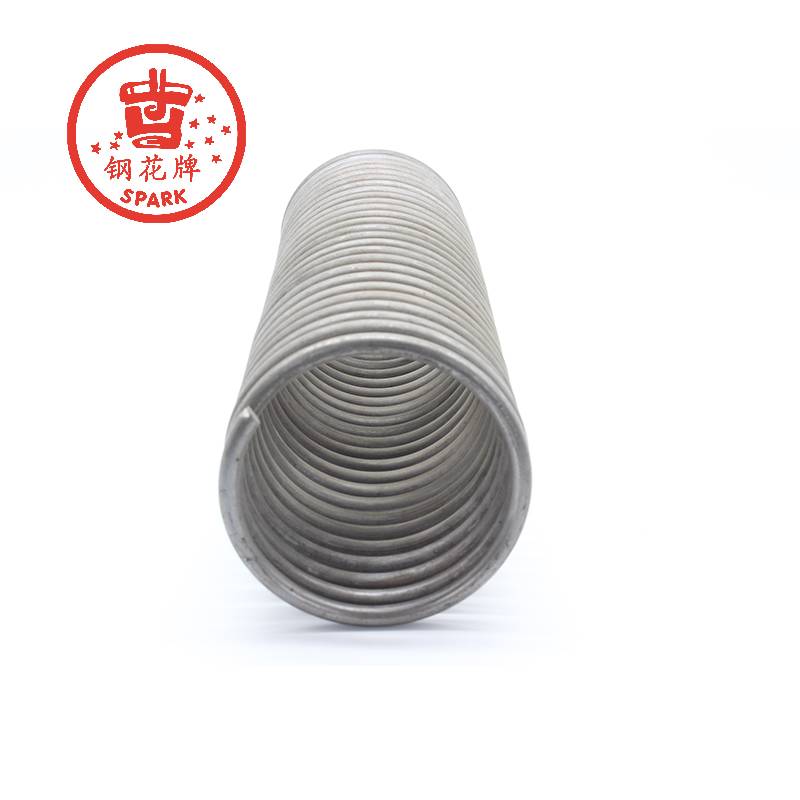

Size range

|

Wire diameter |

Ø0.05—8.0mm |

|

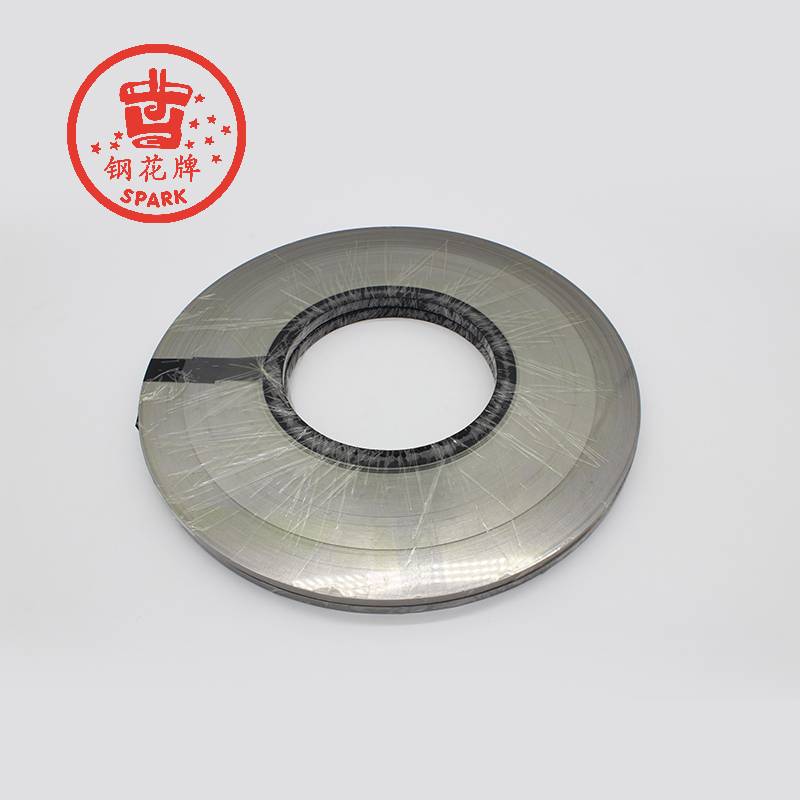

Ribbon |

Thickness 0.08—0.4mm |

|

|

Width 0.5—4.5mm |

|

Strip |

Thickness 0.5—2.5mm |

|

|

Width 5.0—48.0mm |

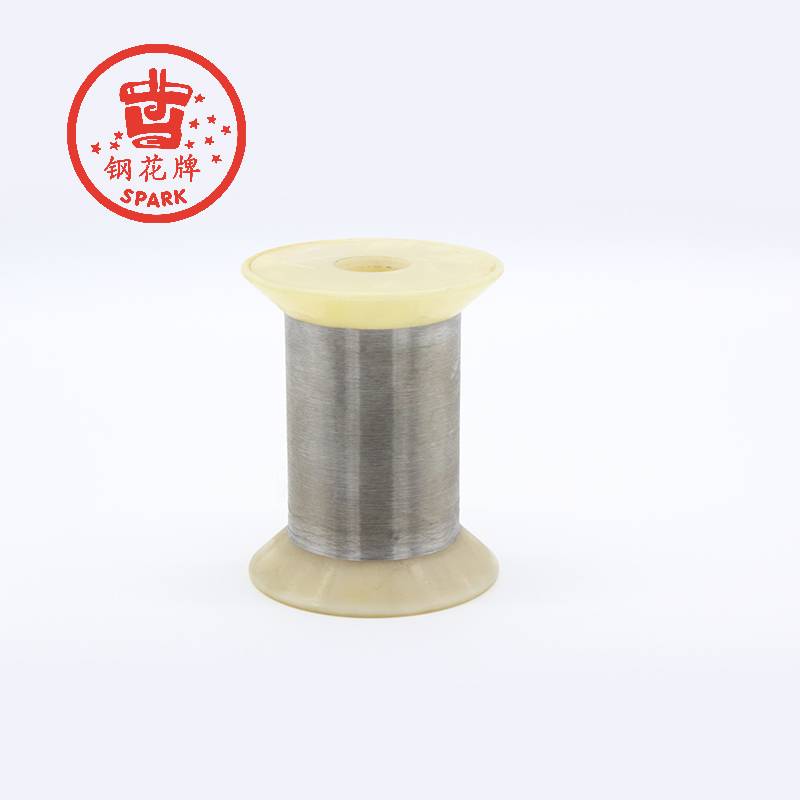

Product detail pictures:

Related Product Guide:

To become the stage of realizing dreams of our employees! To build a happier, much more united and far more professional team! To reach a mutual profit of our clients, suppliers, the society and ourselves for Hot New Products Heat Resistant Insulation For Electrical Wire - Ni-Cr alloys – Shougang , The product will supply to all over the world, such as: Juventus, Finland, Accra, We honor ourselves as a company that comprises of a strong team of professionals who are innovative and well experienced in the international trading, business development and product advancement. Moreover, the company stays unique among its competitors due to its superior standard of quality in production, and its efficiency and flexibility in business support.

In our cooperated wholesalers, this company has the best quality and reasonable price, they are our first choice.