Hot sale Electrical Conductivity Of Alloys - Ni-Cr alloys – Shougang

Hot sale Electrical Conductivity Of Alloys - Ni-Cr alloys – Shougang Detail:

Ni-Cr electrothermal alloy has high temperature strength. It has good toughness and does not easily deform. Its grain structure is not easily changed. The plasticity is better than Fe-Cr-Al alloys. No brittleness after high temperature cooling, long service life, its easy to process and welding, but the service temperature is lower than Fe-Cr-Al alloy. Ni-Cr electrothermal alloys are one of the main products of our company. All resistance heating alloys manufactured by our company are distinguished by uniform composition, high resistivity, stable quality, accurate dimension, long operating life and good processability. Consumers can select the suitable grade according to different requirements.

Steel grades and Chemical composition(GB/T1234-1995)

|

Steel grades |

Chemical composition(%) |

||||

|

|

C |

Si |

Cr |

Ni |

Fe |

|

Cr15Ni60 |

≤0.08 |

0.75-1.6 |

15-18 |

55-61 |

- |

|

Cr20Ni30 |

≤0.08 |

1-2 |

18-21 |

30-34 |

- |

|

Cr20Ni35(N40) |

≤0.08 |

1-3 |

18-21 |

34-37 |

- |

|

Cr20Ni80 |

≤0.08 |

0.75-1.6 |

20-23 |

remain |

≤1 |

|

Cr30Ni70 |

≤0.08 |

0.75-1.6 |

28-31 |

remain |

≤1 |

(According to the needs of customers, we can provide alloys in accordance with the enterprise standards, such as American standard, Japanese standard, German standard and other standards)

Properties and Applications

|

Steel grades |

Max.continuous operating temperature℃ |

Tensile strength N/mm2 |

Elongation at rupture(approx.)% |

Electrical resistivity μ·Ω·m |

|

Cr15Ni60 |

1150℃ |

700-900 |

>25 |

1.07-1.20 |

|

Cr20Ni30 |

1050℃ |

700-900 |

>25 |

0.99-1.11 |

|

Cr20Ni35(N40) |

1100℃ |

700-900 |

>25 |

0.99-1.11 |

|

Cr20Ni80 |

1200℃ |

700-900 |

>25 |

1.04-1.19 |

|

Cr30Ni70 |

1250℃ |

700-900 |

>25 |

1.13-1.25 |

Size range

|

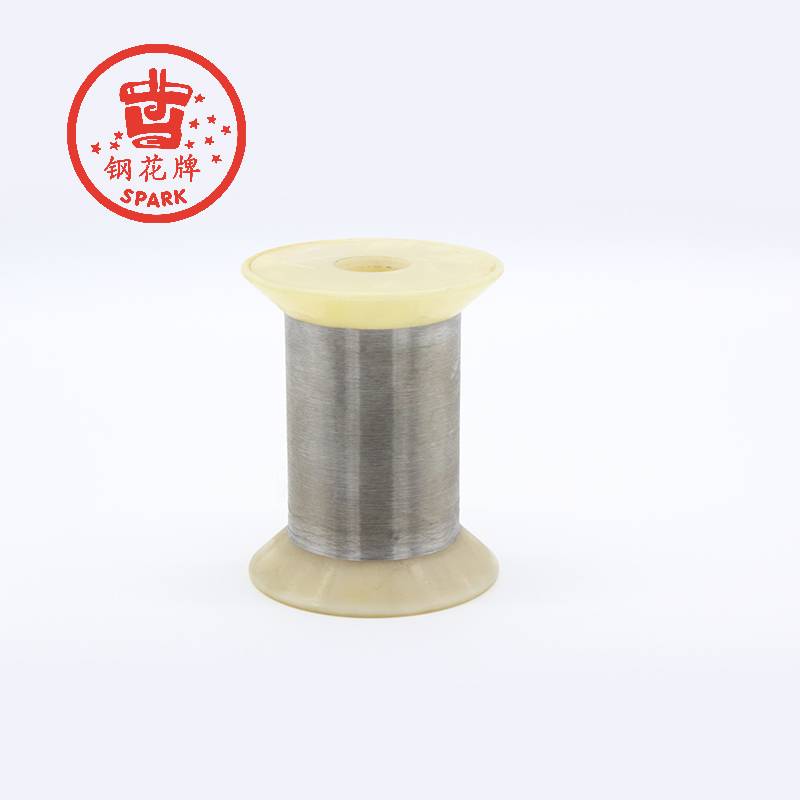

Wire diameter |

Ø0.05—8.0mm |

|

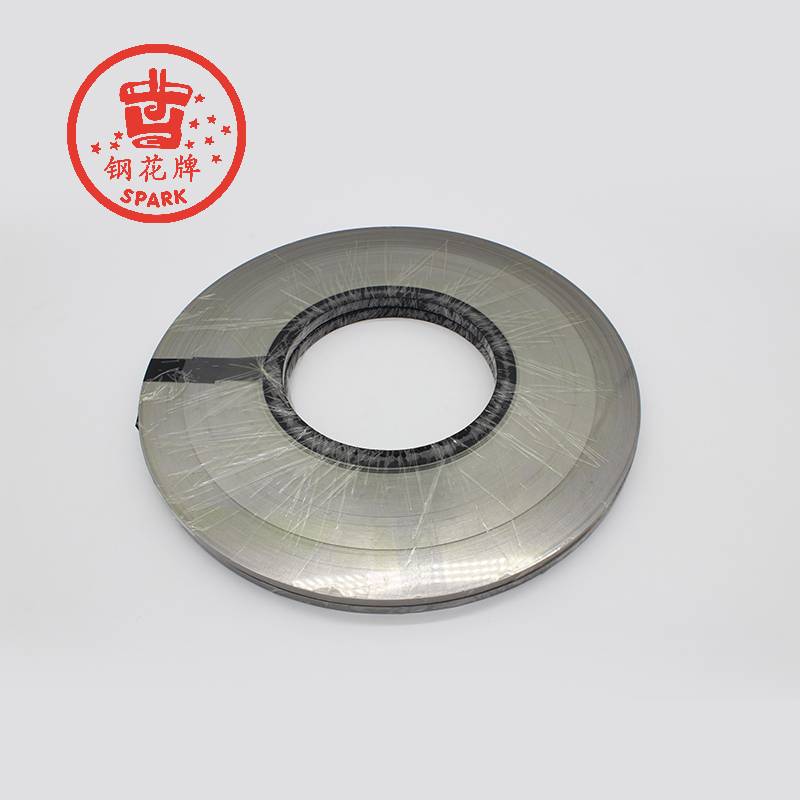

Ribbon |

Thickness 0.08—0.4mm |

|

|

Width 0.5—4.5mm |

|

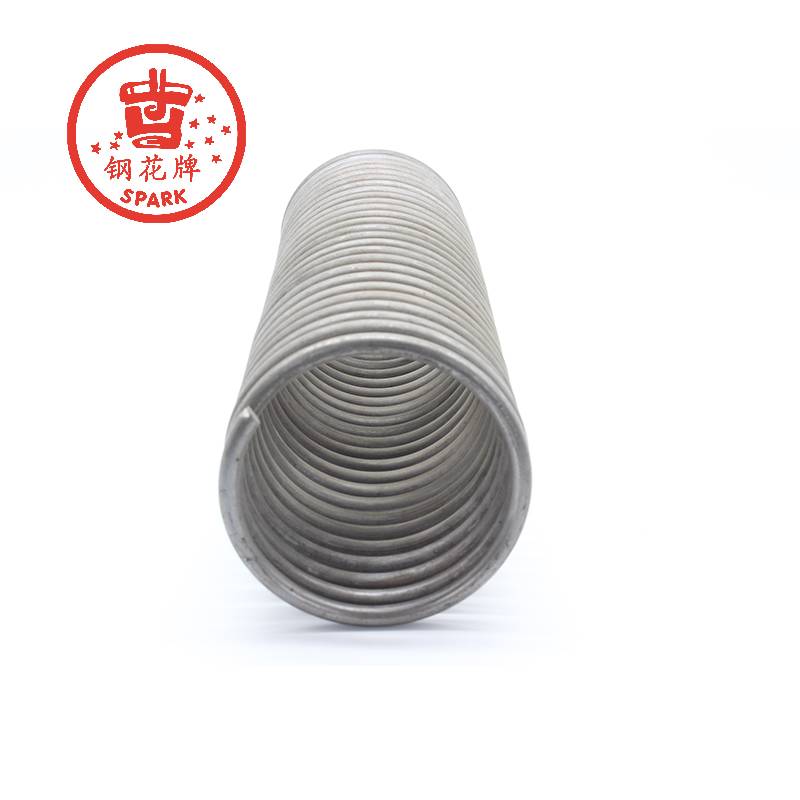

Strip |

Thickness 0.5—2.5mm |

|

|

Width 5.0—48.0mm |

Product detail pictures:

Related Product Guide:

Our intention should be to fulfill our consumers by offering golden provider, superior price and superior quality for Hot sale Electrical Conductivity Of Alloys - Ni-Cr alloys – Shougang , The product will supply to all over the world, such as: Jeddah, Bangalore, Paris, We have a strict and complete quality control system, which ensures that each product can meet quality requirements of customers. Besides, all of our products have been strictly inspected before shipment.

The goods are very perfect and the company sales manager is warmful, we will come to this company to purchase next time.