OEM Factory for Heat Resistant Wire For Oven - HRE resistance heating wire – Shougang

OEM Factory for Heat Resistant Wire For Oven - HRE resistance heating wire – Shougang Detail:

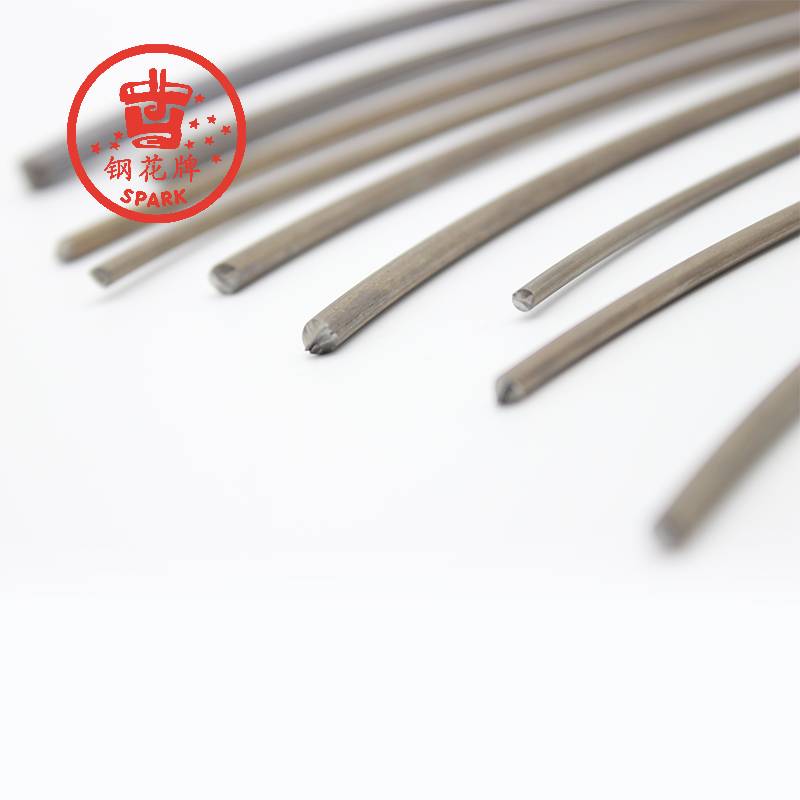

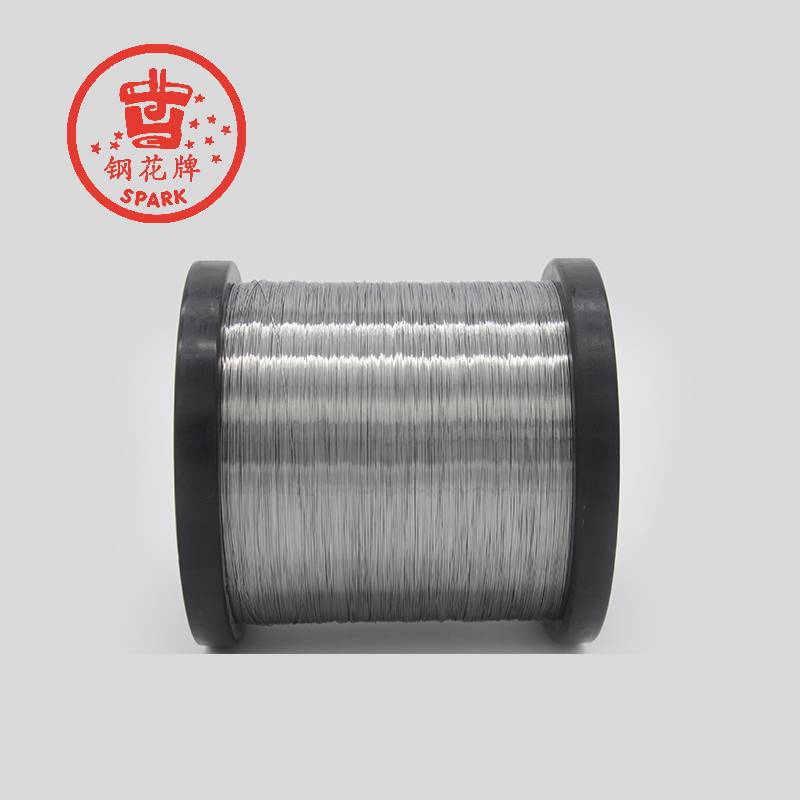

HRE resistance heating wire is used for high-temperature furnace. Its characteristics are: high temperature resisting, long operating life, good oxidation resistance, excellent entanglement at room temperature, good process ability, back to the flexibility of small, and its processing performance is better than 0Cr27Al7Mo2 and high temperature performance is batter than 0Cr21Al6Nb, the use of the temperature can resch 1400℃.

Size range:

∮0.5-∮10.0mm

Use: We can supply special size from customer requirement about HRE.

HRE mainly used for powder metallurgy furnace, diffusion furnaces, radiant tube heating furnace and a variety of high-temperature heating furnace body.

|

HRE |

Cr |

Al |

Re |

Fe |

|

25.0 |

6.0 |

Appropriate |

Rest |

|

|

Max.continuous operature(℃) |

1.0-3.0 |

>3.0 |

||

|

1225-1350 |

1400 |

|||

|

Electrical resistivity at 20℃(μ·Ω·m) |

1.45 |

|||

|

Density(g/cm3) |

7.10 |

|||

|

Melting point(approx.)(℃) |

1500 |

|||

|

Elongation at rupture(approx.)(%) |

16-33 |

|||

|

Exprss life expectancy(1350℃,h) |

>60 |

|||

|

The number ofrepeated bending(20℃) |

7-12 |

|||

|

Magnetic properties |

Magnetic |

|||

The relationship between Maximum use of furnace temperature and atmosphere :

|

Furnace atmosphere |

Dry air |

Moist air |

Hydrogen |

Nitrogen

|

Decomposition of ammonia gas |

|

Temperature() |

1400 |

1200 |

1400 |

950 |

1200 |

Helping

1. Rated voltage: 220V/380V

2. The installation process to avoid bump, to avoid the tainted dirt, to avoid damp, to wear gloves when you are hand-held wire. After installation furnace wire should remain straight, to prevent surface scratches and erosion by dirt, so affect the useful life and improper installation;

3. When you use at rated voltage. In strong reducing atmosphere, acid atmosphere, moist atmosphere will affect the service life of high temperature use;

4. You use before the high temperature, should to stay a few hours and be free from corrosion in the dry atmosphere of about 1000 ℃, so that wire furnace after the protective film formed on the surface of normal use, that can guarantee the life of the normal wire heater;

5. The installation process should keep heater wire insulation installation, at power to avoid touching, to guard against electric shock or scald.

Product detail pictures:

Related Product Guide:

Using a full scientific good quality administration system, very good quality and superior faith, we win good standing and occupied this discipline for OEM Factory for Heat Resistant Wire For Oven - HRE resistance heating wire – Shougang , The product will supply to all over the world, such as: Botswana, Turkmenistan, Iraq, We can give our clients absolute advantages in product quality and cost control, and we have full range of molds from up to one hundred of factories. As product updating fast, we succeed in developing many high quality products for our clients and get high reputation.

The product manager is a very hot and professional person, we have a pleasant conversation, and finally we reached a consensus agreement.