OEM/ODM China Electric Heating Wires - Ni-Cr alloys – Shougang

OEM/ODM China Electric Heating Wires - Ni-Cr alloys – Shougang Detail:

Ni-Cr electrothermal alloy has high temperature strength. It has good toughness and does not easily deform. Its grain structure is not easily changed. The plasticity is better than Fe-Cr-Al alloys. No brittleness after high temperature cooling, long service life, its easy to process and welding, but the service temperature is lower than Fe-Cr-Al alloy. Ni-Cr electrothermal alloys are one of the main products of our company. All resistance heating alloys manufactured by our company are distinguished by uniform composition, high resistivity, stable quality, accurate dimension, long operating life and good processability. Consumers can select the suitable grade according to different requirements.

Steel grades and Chemical composition(GB/T1234-1995)

|

Steel grades |

Chemical composition(%) |

||||

|

|

C |

Si |

Cr |

Ni |

Fe |

|

Cr15Ni60 |

≤0.08 |

0.75-1.6 |

15-18 |

55-61 |

- |

|

Cr20Ni30 |

≤0.08 |

1-2 |

18-21 |

30-34 |

- |

|

Cr20Ni35(N40) |

≤0.08 |

1-3 |

18-21 |

34-37 |

- |

|

Cr20Ni80 |

≤0.08 |

0.75-1.6 |

20-23 |

remain |

≤1 |

|

Cr30Ni70 |

≤0.08 |

0.75-1.6 |

28-31 |

remain |

≤1 |

(According to the needs of customers, we can provide alloys in accordance with the enterprise standards, such as American standard, Japanese standard, German standard and other standards)

Properties and Applications

|

Steel grades |

Max.continuous operating temperature℃ |

Tensile strength N/mm2 |

Elongation at rupture(approx.)% |

Electrical resistivity μ·Ω·m |

|

Cr15Ni60 |

1150℃ |

700-900 |

>25 |

1.07-1.20 |

|

Cr20Ni30 |

1050℃ |

700-900 |

>25 |

0.99-1.11 |

|

Cr20Ni35(N40) |

1100℃ |

700-900 |

>25 |

0.99-1.11 |

|

Cr20Ni80 |

1200℃ |

700-900 |

>25 |

1.04-1.19 |

|

Cr30Ni70 |

1250℃ |

700-900 |

>25 |

1.13-1.25 |

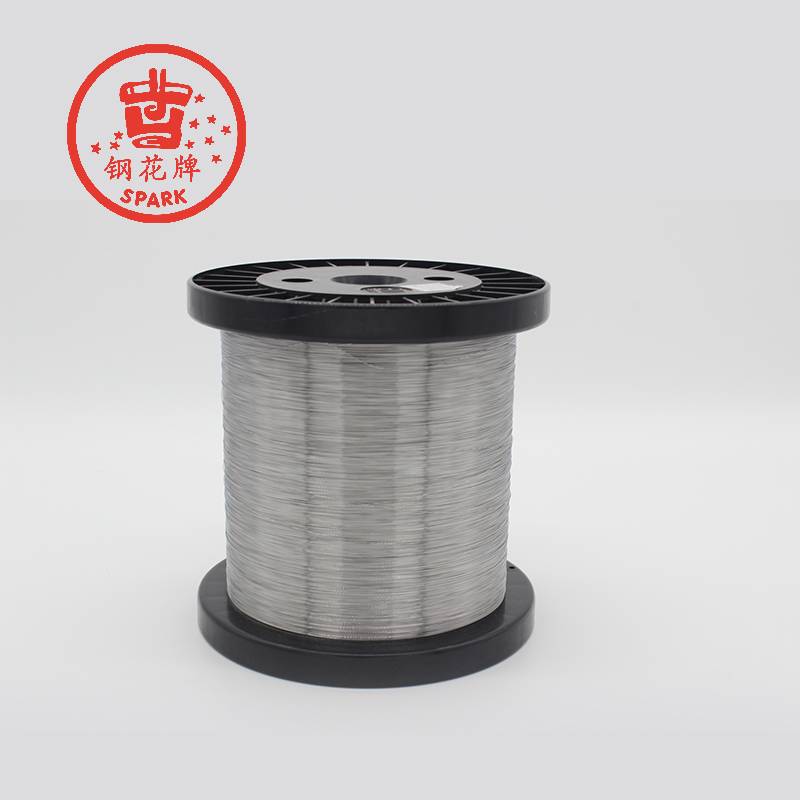

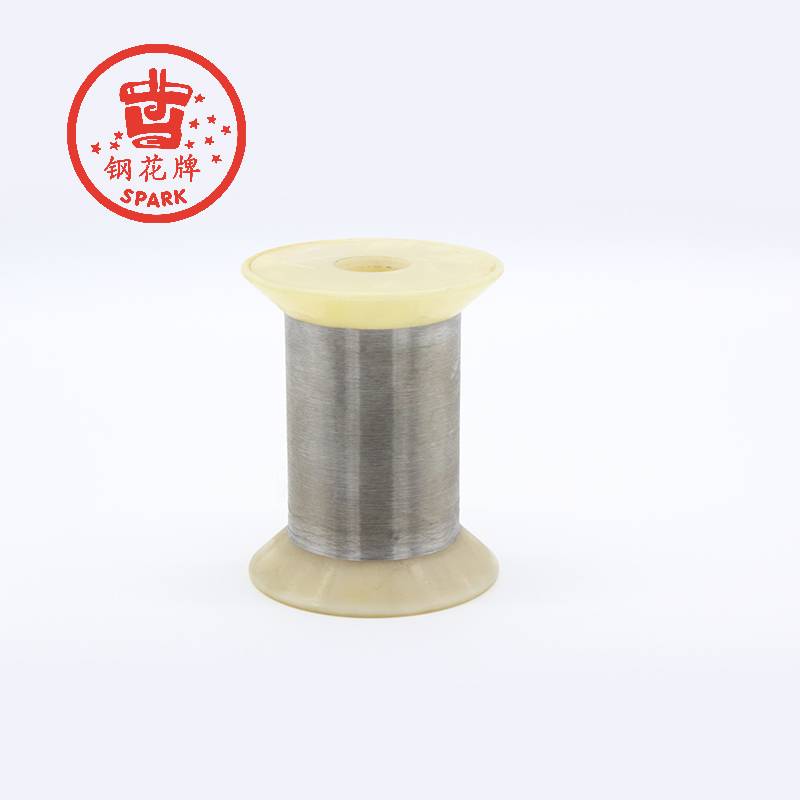

Size range

|

Wire diameter |

Ø0.05—8.0mm |

|

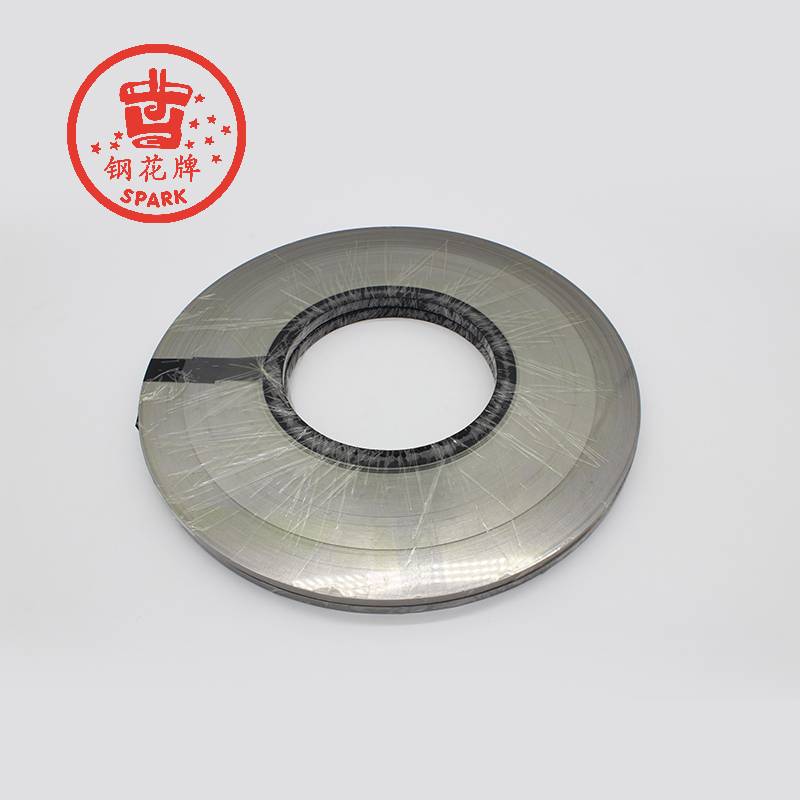

Ribbon |

Thickness 0.08—0.4mm |

|

|

Width 0.5—4.5mm |

|

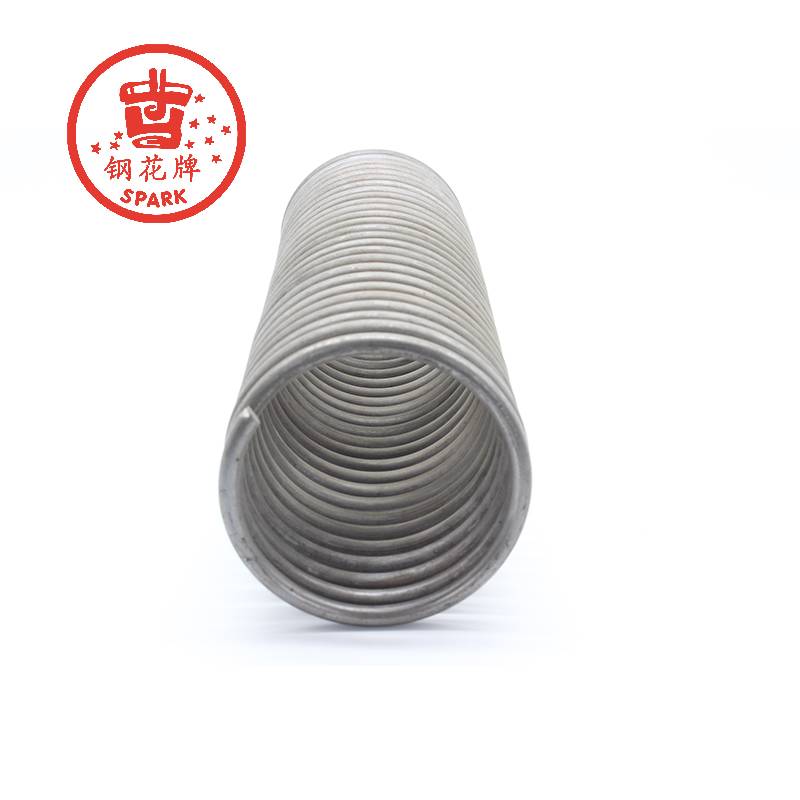

Strip |

Thickness 0.5—2.5mm |

|

|

Width 5.0—48.0mm |

Product detail pictures:

Related Product Guide:

Our personnel are generally in the spirit of "continuous improvement and excellence", and together with the outstanding top quality merchandise, favorable price tag and fantastic after-sales solutions, we try to gain every single customer's rely on for OEM/ODM China Electric Heating Wires - Ni-Cr alloys – Shougang , The product will supply to all over the world, such as: Danish, Greek, Provence, We welcome an opportunity to do business with you and hope to have pleasure in attaching further details of our products. Excellent quality, competitive price, punctual delivery and dependable service can be guaranteed. For further inquires please do not hesitate to contact us.

We are a small company that has just started, but we get the company leader's attention and gave us a lot of help. Hope we can make progress together!