Short Lead Time for Alloy Heating Wire Manufacturer - SGHYZ high temperature electrothermal alloy – Shougang

Short Lead Time for Alloy Heating Wire Manufacturer - SGHYZ high temperature electrothermal alloy – Shougang Detail:

BEIJING SHOUGANG GITANE NEW MATERIALS CO.LTD has long been committed to the research and development of electric heating alloy products with good oxidation resistance and high temperature resistance. SGHYZ product is a new product developed after HRE which has been widely used in high temperature electrothermal alloy materials in recent years. Compared with HRE, SGHYZ product has higher purity and better oxidation resistance. With the special rare earth element collocation and unique metallurgical manufacturing process, the material has been recognized by domestic and foreign customers in the field of high-temperature heat-resistant fiber. It has been successfully applied in ceramic sintering, diffusion furnace, high power density and high temperature industrial kiln.

1. grades and chemical composition%

| C | Si | Cr | Al | Fe |

| ≤0.04 | ≤0.4 | 20-23 | 5.8 | - |

2. Specifications

(1) Diameter of round wire:φ0.15-9.0mm

(2) Flat wire thickness:0.1-0.4mm Width:0.5-4.5mm

(3)Strip thickness: 0.5-2.5 Width:5-48mm

3. Delivery status

(1) The diameter of the wire is larger than 5.0 mm,Blue disc delivery

(2) Wire diameter range: 1.0-5.0 mm, golden plate delivery

(3) Wire diameter range is less than or equal to φ 1.0 mm, bright axial delivery

(4) Flat belt: delivered in polished condition.

4. Performance and Application

(1). Basic application

| Maximum usetemperature℃ | Annealed tensile strength N/mm2 | Elongation % | 20℃resistancerateμ.Ω.m |

|

1425 |

650-800 |

>14 |

1.45 |

Application: High temperature ceramic firing furnace / high temperature heat treatment furnace / high temperature diffusion in electronic industry

(2).Characteristics

| densityg/cm3 | 1000℃high temperaturestrength MPa | 1350 ℃ fast life (hoursAccording to GB / t13300-91 standard | Completely oxidized stateRadiation coefficient of |

| 7.1 | 20 | >80 | 0.7 |

(3)、Average linear expansion coefficient

| temperature℃ | Average linear expansion coefficien×10-6/k |

| 20-250 |

11 |

| 20-500 |

12 |

| 20-750 |

14 |

| 20-1000 |

15 |

(4).Resistance temperature correction factor

| temperature℃ | 700 | 900 | 1100 | 1200 | 1300 |

| Ct | 1.02 | 1.03 | 1.04 | 1.04 | 1.04 |

5. Relative life

| Wire specifications(mm) | Resistance(Ω/m) | Weight(g/m) |

| 1 | 1.85 | 5.58 |

| 1.1 | 1.53 | 6.75 |

| 1.2 | 1.28 | 8.03 |

| 1.3 | 1.09 | 9.42 |

| 1.4 | 0.942 | 10.9 |

| 1.5 | 0.821 | 12.5 |

| 1.6 | 0.721 | 14.3 |

| 1.7 | 0.639 | 16.1 |

| 1.8 | 0.57 | 18.1 |

| 1.9 | 0.511 | 20.1 |

| 2 | 0.462 | 22.3 |

| 2.1 | 0.419 | 24.6 |

| 2.2 | 0.381 | 27 |

| 2.3 | 0.349 | 29.5 |

| 2.4 | 0.321 | 32.1 |

| 2.5 | 0.295 | 34.9 |

| 2.6 | 0.273 | 37.7 |

| 2.7 | 0.253 | 40.7 |

| 2.8 | 0.235 | 43.7 |

| 2.9 | 0.22 | 46.9 |

| 3 | 0.205 | 50.2 |

| 3.1 | 0.192 | 53.6 |

| 3.2 | 0.18 | 57.1 |

| 3.3 | 0.17 | 60.7 |

| 3.4 | 0.16 | 64.5 |

| 3.5 | 0.151 | 68.3 |

| 3.6 | 0.142 | 72.3 |

| 3.7 | 0.135 | 76.3 |

| 3.8 | 0.128 | 80.5 |

| 3.9 | 0.121 | 84.8 |

| 4 | 0.115 | 89.2 |

| 4.1 | 0.11 | 93.7 |

| 4.2 | 0.105 | 98.4 |

| 4.3 | 0.1 | 103.1 |

| 4.4 | 0.095 | 108 |

| 4.5 | 0.0912 | 113 |

| 4.6 | 0.0873 | 118 |

| 4.7 | 0.0836 | 123 |

| 4.8 | 0.0801 | 128 |

| 4.9 | 0.0769 | 134 |

| Wire specifications(mm) | Resistance(Ω/m) | Weight(g/m) |

| 5 | 0.0739 | 139 |

| 5.1 | 0.071 | 145 |

| 5.2 | 0.0683 | 151 |

| 5.3 | 0.0657 | 157 |

| 5.4 | 0.0633 | 163 |

| 5.5 | 0.061 | 169 |

| 5.6 | 0.0589 | 175 |

| 5.7 | 0.0568 | 181 |

| 5.8 | 0.0549 | 188 |

| 5.9 | 0.053 | 194 |

| 6 | 0.0513 | 201 |

| 6.1 | 0.0496 | 207 |

| 6.2 | 0.048 | 214 |

| 6.3 | 0.0465 | 221 |

| 6.4 | 0.0451 | 228 |

| 6.5 | 0.0437 | 236 |

| 6.6 | 0.0424 | 243 |

| 6.7 | 0.0411 | 250 |

| 6.8 | 0.0399 | 258 |

| 6.9 | 0.0388 | 265 |

| 7 | 0.0377 | 273 |

| 7.1 | 0.0366 | 281 |

| 7.2 | 0.0356 | 289 |

| 7.3 | 0.0346 | 297 |

| 7.4 | 0.0337 | 305 |

| 7.5 | 0.0328 | 314 |

| 7.6 | 0.032 | 322 |

| 7.7 | 0.0311 | 331 |

| 7.8 | 0.0303 | 339 |

| 7.9 | 0.0296 | 348 |

| 8 | 0.0288 | 357 |

| 8.1 | 0.0281 | 366 |

| 8.2 | 0.0275 | 375 |

| 8.3 | 0.0268 | 384 |

| 8.4 | 0.0262 | 393 |

| 8.5 | 0.0256 | 403 |

| 8.6 | 0.025 | 412 |

| 8.7 | 0.0244 | 422 |

| 8.8 | 0.0238 | 432 |

| 8.9 | 0.0233 | 442 |

SGHYZ meter resistance / weight reference table. (the above calculation data are only for reference, the resistance fluctuation range is ± 5%, and the weight varies with the size accuracy range.)

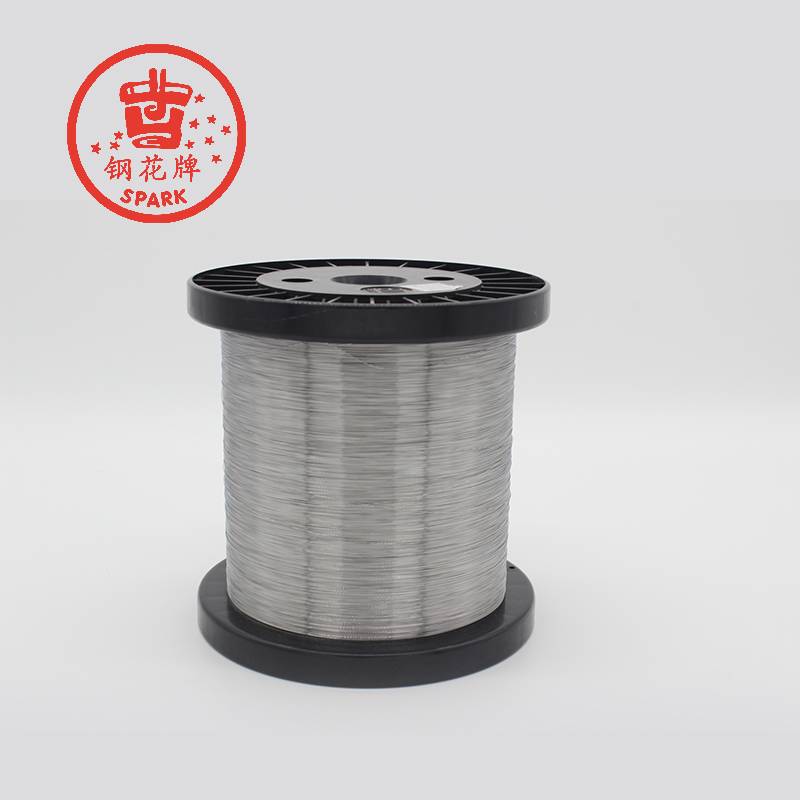

Product detail pictures:

Related Product Guide:

We know that we only thrive if we can guarantee our combined rate competiveness and good quality advantageous at the same time for Short Lead Time for Alloy Heating Wire Manufacturer - SGHYZ high temperature electrothermal alloy – Shougang , The product will supply to all over the world, such as: Southampton, Congo, Sao Paulo, We have more than 8 years of experience in this industry and have a good reputation in this field. Our products have won praise from customers worldwide. Our aim is to help customers realize their goals. We are making great efforts to achieve this win-win situation and sincerely welcome you to join us.

The company has a good reputation in this industry, and finally it tured out that choose them is a good choice.